- Detail

- Parameters

- Review

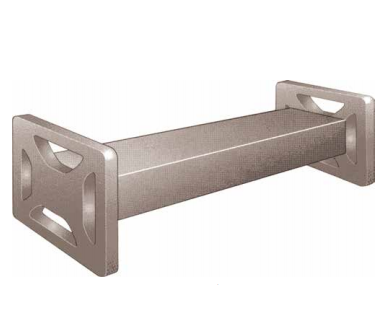

Ditch Magnet

Application:

The ditch magnet is the most effective means of trapping and removing metal particles from the drilling mud that are not filtered by the shale shaker. This unit will capture all metals through magnetic attraction and hold them until they can be removed from the mud stream. The magnet is particularly valuable and useful during milling operations. Removal of mill cuttings and debris reduces wear of mud pumps, drill bit and other equipment. It eliminates problems caused by the harmful debris that are returned to the downhole with the drilling mud. They are equally effective during washover and fishing operations.

Structure:

The ditch magnet is made of a high performance magnet with strong magnetic field. It is simple, rugged and has high power to weight ratio.

Operation:

Ditch magnet is easy to operate. It is most effective when suspended by soft line in the mud ditch or shaker discharge. When the cuttings or debris attached are full, it should be removed and cleaned. Remove the magnet from the mud ditch and open the inserting plate from the end with the pull rod. When the magnetic pole body is pulled out, all cuttings and debris will drop off. The magnet body shall be cleaned with fresh water and assemble again for use.

Maintenance:

Frequency of cleaning for the unit per day is directly dependent on the milling rate. Higher milling rate will mean high cleaning frequency.To clean the unit, remove the Magnet and clean it with fresh or salt water hose. Wipe all cuttings from the unit and assemble it back for normal operation. During other operations when there are less return cuttings or metal shavings, the unit need not be cleaned so frequently.

Technical specification:

| Model | OD (mm) | Magnetic Effective Area(mm) | Strength of Magnetic Pole Surface (Gs) | Strength From 10mm To Magnetic Pole Surface (Gs) |

| 18'' | 200×460 | 125×400 | 1400 | 700 |

| 24'' | 200×620 | 125×525 | 1400 | 700 |

| 36'' | 200×920 | 125×825 | 1400 | 700 |