- Detail

- Parameters

- Review

Type of Junk Mill:

Flat Bottom Junk Mill,Tapered Mills,Concave Junk Mills,Econo mill,Bladed Junk Mill,String Junk Mill,Pilot Mill,Skirted Junk Mill

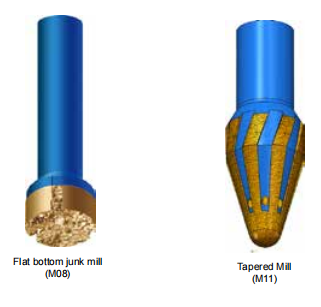

Flat Bottom Junk Mill

The Flat Bottom Junk Mill is the most commonly used milling tool. It is designed to mill a wide variety of junk such as squeeze tools, packers, tubing, bridge plugs and similar objects.

Tapered Mills

The Tapered Mill is designed for milling through various types of downhole obstructions, and reaming out liners and whipstock windows. It works well in collapsed casing as well as tight spots.

Concave Junk Mills

The Concave Mill is designed for milling bit cones and other loose objects. It keeps the fish in a centralized fix location under the mill for greater milling effectiveness.

Economill

The Economill is an effective tool for light duty milling jobs such as packers, bridge plug, and cement. This mill can be easily make-up and break-out with standard bit breakers.

Bladed Junk Mill

Bladed Junk Mill is dressed with high- quality tungsten carbide to ensure optimal performance in all applications. They are suitable for all types of general junk milling, as well as for removing packers, retainers, and squeeze tools.

String Junk Mill

The String Mill is designed to clean casing and whipstock windows. Its short leading and trailing angles, allow the mill to clean "bird nest" and other obstructions in the string, while the bottomhole tool is milling. This string mill assures that the milled section maintains full gage.

![]()

Pilot Mill

The Pilot Mill is best used for milling stuck tubular tools, such as liner, liner hanger, wash pipe, rotary shoe or drill pipe. The pilot assembly keeps the tubular tools in a centered position, while the milling blades mill the product away.

Skirted Junk Mill

The Skirted Junk Mill is designed for milling tubular fish, either inside casing or in open hole. Should the fish be plugged, it is far better to use a shoe- type guide with a flat mill to avoid sidetracking.