- Detail

- Parameters

- Review

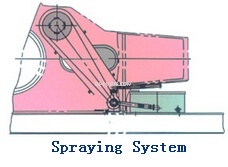

The spraying system consists mainly of spray pump, cooling water tank and spraypipe, and the function is to cool and wash liners and pistons when the pump isrunning, prolonging their

service life.

The centrifugal spray pump can be driven by a sheavemounted at the pinion end or a separate

motor. The water is used as thecooling-lubrication fluid.

The spray pipe is mounted on the coupling between theextension rod and the piston rod and

reciprocates with the piston. The nozzleis adjacent to the piston end, therefore, the cooling

lubricating fluid canwash the contact surface of pistons and liners all the time. The durable

fixedspray pipe may be used, too.

Spray Pump Assembly(BC136223-0800)

1 BC136223-080100 Spray pump bracket 2

2 AH160201-1201B3 Backing plate 4

3 AH220201-0805B1 Joint ZG2 1/2″1

4 AH220201-080300B1 Suction flange 1

5 AH220201-0804B1 Seal gasket 2

6 GB/T5781 Bolt M12×55-4.8-Zn.D 8

7 AH220201-0802B1 Discharge flange NPT1″ 1

8 AH130101-080400B1 Water tank 1

9 AH100101-080900 Hose joint φ22×φ37 2

10 AH130101-080700 Cover 1

11 TTA6512-460 Pipe R2 1/2″×NPT2 1/2″ 1

12 AH100101-0806 Joint G1″-M33×2 1

13 AH100101-0804 Short pipe NPT1″-G1″ 1

14 GB/T 5782 Blot M12×40-4.8-Zn.D 4

15 GB/T 6170 Nut 12-5-Zn.D 8

16 GB/T 93 Spring gasket 12 12

17 140501010510106200 Hose L=360 1

18 GB/T 3289.2 90°elbow Rc2 1/2″ 1

19 140501010220100000 Hose L=1500 1

20 Q11F-16 Stainless internal thread ball valve G1″ 1

21 Centrifugal pump 32SB180J-100 1

22 T515-103.00 Oil draining device 2