- Detail

- Parameters

- Review

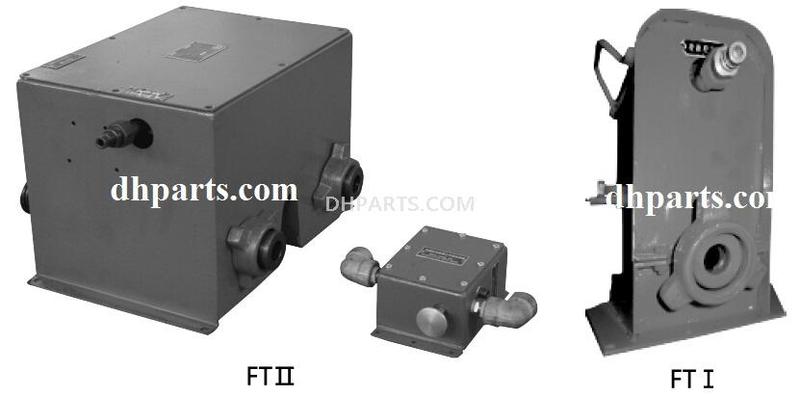

Model available at FT1 & FT2, anti-lifting safety devices are used to brake safely when close the well bore.

Hydraulic blowout preventer (BOP) is pretty important safety equipment to prevent blow outing during petroleum and natural gas exploration and exploitation. But it is possible that BOP and drilling pipe could be damaged because of lifting pipe after the BOP is closed as design limitation of well control equipment or user’s unintended operation. In fact, those cases occur often, and case lots of damage.

Antilifting safety devices provided by us have the performance of easy installation, convenient operation, and liable function. It can prevent lifting drilling pipes after pipe rams are closed, so it can protect pipe rams, pipes.

1)Antilifting Safety Device Box is installed within the close pipe of pipe rams of BOP control system. FT2 type suits for two pipe preventers and FT1 type suits for one pipe preventer.

Remarks: Different factories have different unions or joints, so in order to install right, proper unions or joints should be replaced

2)Manual Control Box (TF2-05-00) should be installed beside the driller on the platform.

3)Brake Cylinder Assembly, including shuttle valve and quick exhaust valve, can be installed freely according to the rig. And the installation schematic is only one of the kinds of installation positions.

Remarks: Normally, the brake cylinder assembly is fixed between overrunning valve and charging valve, or between crown block protector and charging valve.Remove the air hose at the charging valve between original crown block protector (or overrunning valve),and then connect to the inlet “ TO CROWN BLOCK PROTECTOR” of shuttle valve of the brake cylinder assembly, and the outlet of the shuttle valve of the brake cylinder assembly connects charging vale.

Ordering Notes

a) One or two pipe rams preventers are equipped, if one pip rams, FT1 should be selected. And if two pipe rams FT2 should be selected.

b) FT1 be suit for one pipe rams preventer and it can match other factory’s BOP control system

c) FT2 type has one ore pipe rams oil circuit than FT1, it is suit for one or two pipe rams preventers. It has higher efficiency.

d) Whether drying chamber and prevent frostbite pump are needed.

Standard equipment list

Item | Description | Specification | Qty | Remarks |

1 | FT1/2 type anti-lifting safety device box | Assembly | 1 set | FT1A-02-00/FT2-03-00 |

2 | Manual Control Box | Assembly | 1 set | FT2-05-00, with J8-00 quick self sealing joint at the inlet and outlet. |

3 | Brake Cylinder Assembly | Assembly | 1 set | P port equipped with quick self sealing joint, B port equipped with male-female elbow, outlet equipped with double male joint. |

4 | Air Hose | 15m | 3 pcs | FT2-01-00A air hose equipped with female quick self-sealing joint. |

5 | 1/ 2” Elbow | Double Male ZG 1/2” | 1 pcs | It can be installed on the outlet of the driller’s panel. |

6 | 1/2” Elbow | Double Female ZG 1/2” | 1 pcs | It can be installed on the outlet of the driller’s panel. |

7 | Double Male | Z 1/2” *Z 3/8” Joint | 1 pcs | FT2-10 |

8 | Double Male | Z 3/4” *Z 3/8” Joint | 1 pcs | FT2-11 |

9 | Male-Female Joint | Z 1/2” Female * Z 3/8” Male Joint | 1 pcs | FT2-13 |

10 | Male-Female Joint | Z 3/4” Female * Z 3/8” Male Joint | 1 pcs | FT2-14 |

11 | O-Ring | 40*3.5 | 1 pcs | |

12 | O-Ring | 24*2.4 | 1 pcs | |

13 | O-Ring | 20*2.4 | 1 pcs | |

14 | O-Ring | 16*2.4 | 6 pcs | |

15 | O-Ring | 14*2.4 | 1 pcs | |

16 | O-Ring | 10*1.9 | 1 pcs | |

17 | Operation Instruction | 1 pcs | ||

18 | Qualified Certificate | 1 pcs |